In the world of building things, there’s this important stuff called TMT bars. They’re strong steel bars that help make structures like buildings and bridges sturdy. But here’s the thing: cutting and bending these bars the old-fashioned way is hard work and takes a lot of time.

Understanding TMT Bars

Before delving into the intricacies of the cutting and bending machine, it’s essential to grasp the significance of TMT bars in construction. TMT bars are steel bars that undergo a specialized manufacturing process involving heat treatment and mechanical manipulation. This process enhances their strength, ductility, and corrosion resistance, making them ideal for reinforcing concrete structures.

Challenges with Traditional Methods

Traditionally, cutting and bending TMT bars on construction sites involved manual labor and handheld tools. Workers would spend considerable time and effort measuring, cutting, and bending each bar to precise specifications. Not only was this process laborious, but it also led to inconsistencies and errors, compromising the structural integrity of the final product. Additionally, the manual handling of heavy steel bars posed safety risks for workers.

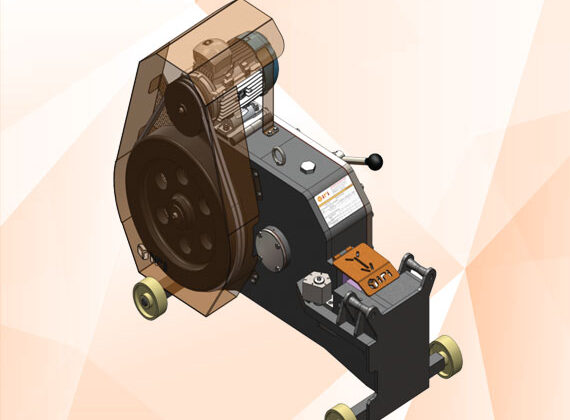

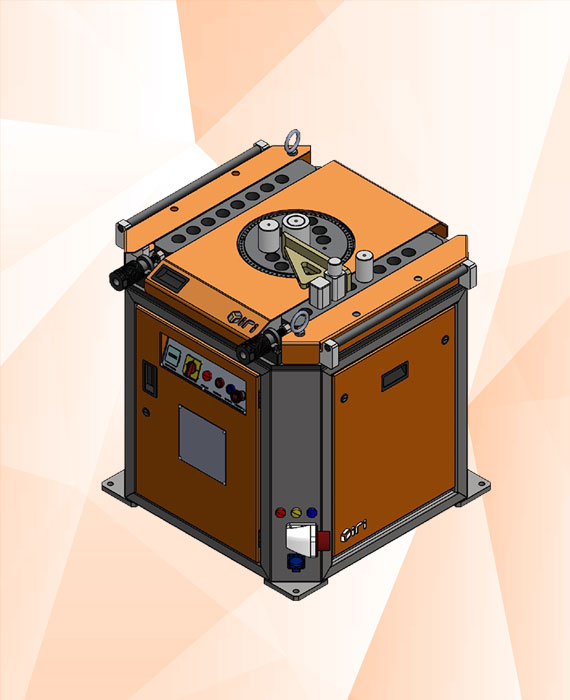

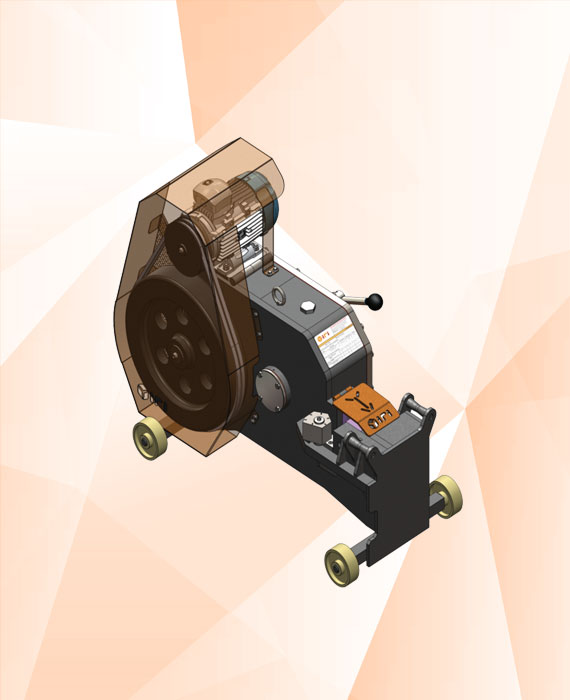

The Advent of TMT Bar Cutting and Bending Machines

The introduction of TMT Bar Cutting and Bending Machines revolutionized the way TMT bars are processed in the construction industry. These machines are equipped with advanced technology and precision-engineered components to automate the cutting and bending process with unparalleled accuracy and efficiency.

Features and Benefits

- Precision Cutting: TMT Bar Cutting machine and Bending Machines are capable of cutting TMT bars to precise lengths with minimal deviation. This ensures uniformity and consistency in the construction process, resulting in stronger and more reliable structures.

- Efficient Bending: These machines can bend TMT bars into various shapes and angles according to the specific requirements of the construction project. From simple bends to complex geometries, the machine can execute bending tasks swiftly and accurately.

- Time and Labor Savings: By automating the cutting and bending process, these machines significantly reduce the time and labor required for construction projects. What would have taken hours or even days to accomplish manually can now be completed in a fraction of the time with minimal human intervention.

- Enhanced Safety: With automated operation, TMT Bar Cutting and Bending Machines minimize the risk of accidents and injuries associated with manual handling of heavy steel bars. Workers can operate the machine from a safe distance, reducing the likelihood of workplace incidents.

- Versatility: These machines are designed to accommodate TMT bars of various sizes and diameters, making them suitable for a wide range of construction applications. Whether it’s a small residential project or a large-scale infrastructure development, the machine can adapt to the specific needs of the project.

Conclusion

Innovation is the driving force behind progress, and the TMT Bar Cutting and TMT bar Bending Machine exemplify this principle in the construction industry. By leveraging automation and advanced technology, these machines have streamlined the process of handling TMT bars, leading to faster construction timelines, improved quality, and enhanced safety standards. As the demand for efficient and sustainable construction practices continues to rise, TMT Bar Cutting and Bending Machines will undoubtedly play a pivotal role in shaping the future of the industry.